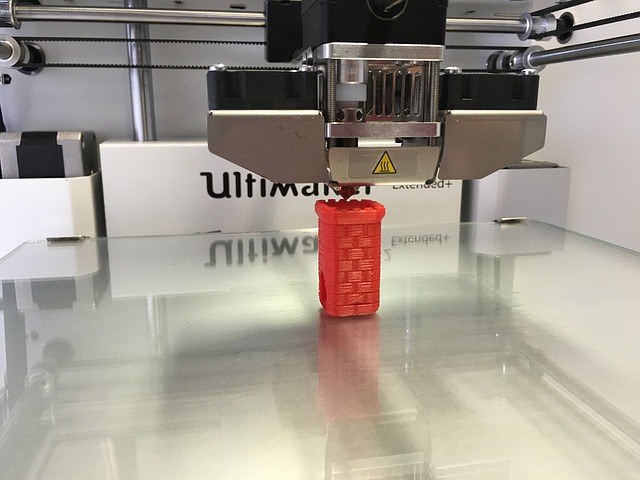

Additive manufacturing is the process of building and creating 3D objects in layers by depositing materials. Additive manufacturing is now more commonly known as 3D printing. When talking about additive manufacturing, there are several advantages of it. Here are some of the advantages of additive manufacturing:

Different industries

Additive manufacturing can be used in a number of different industries. It is a very useful method of manufacturing that can be very useful to be applied to many various industries. The most common and popular use of additive manufacturing can be found in the aerospace industry. There is aerospace metal 3d printing that can help this industry to manufacture components that they need.

Additive manufacturing can be used in a number of different industries. It is a very useful method of manufacturing that can be very useful to be applied to many various industries. The most common and popular use of additive manufacturing can be found in the aerospace industry. There is aerospace metal 3d printing that can help this industry to manufacture components that they need.

Other uses of additive manufacturing can also be found in the industry of marine as well as in the defense industry. The medical industry and the industrial industry also benefit a lot from additive manufacturing.

A wide array of applications

Additive manufacturing can be used and applied to a wide array of several different and various applications across several industries as mentioned before. The applications of additive manufacturing in these industries vary in a wide array of different types. Additive manufacturing can be used in different areas and stages in the process chain. It can be used starting from the research and development stage up until the production and finishing phase.

You can use it to make prototypes and models during the development stage of a product. You can use it to make parts that are for pilot series production in a variety of industries. You can also use it for short series production as well. Other than that, you can use it to produce complex parts too.

Time and cost saving

One of the main advantages of using additive manufacturing is that it increases efficiency. When compared to conventional manufacturing, additive manufacturing is a lot more time saving and cost saving. The volume and the lead time of manufacturing can be minimized by using this method. You are able to manufacture at a low volume, which eliminates programming and tooling, and which leads to saving costs. The lead time of this method is quite short with a time of around one to two weeks and can be delivered within only days.

Customizable complexity

Another great thing about additive manufacturing is that you are able to create something that can cater to your needs and customizable to what you want. Plus, you can create something that is complex and historically was too costly or not possible to achieve with conventional engineering. So, you are able to let your imagination run wild and create something that can benefit you.…

Another great thing about additive manufacturing is that you are able to create something that can cater to your needs and customizable to what you want. Plus, you can create something that is complex and historically was too costly or not possible to achieve with conventional engineering. So, you are able to let your imagination run wild and create something that can benefit you.…