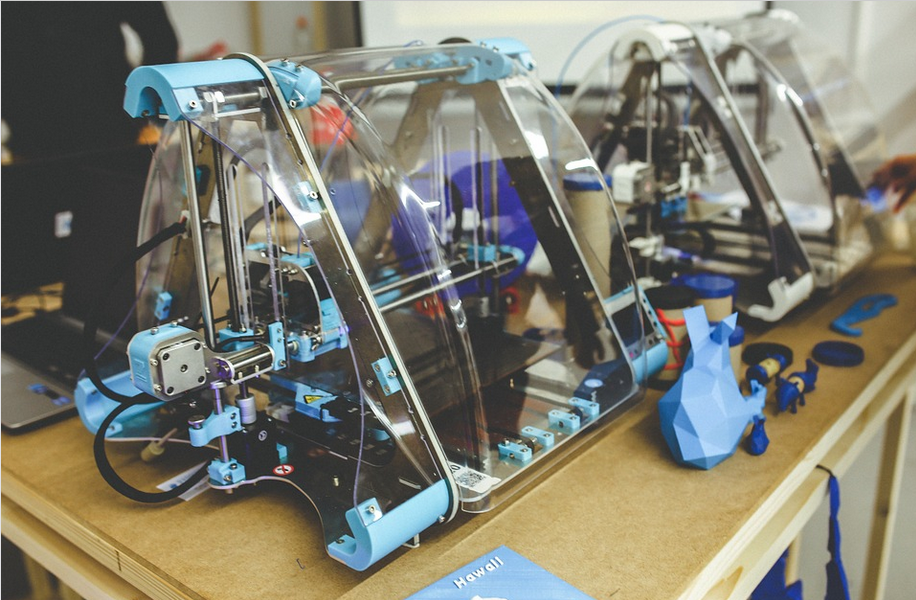

Perhaps you have heard about 3D printing technology. So, what is 3D printing? This is one of the methods used in product development, or transforming an idea to a three-dimensional prototype of the product. Other methods of prototype development are subtractive manufacturing and injection molding.

3D printing is also called additive manufacturing and involves creating 3-dimensional items from computers, and the parts are built by adding material one layer after another. Fortunately, to make great 3-dimension objects, you do not have to worry about looking for the best printer because you can use the best corexy 3d printer .

Here are some of the benefits of 3D printing:

Saves Cost

When you need small production runs or applications, you can use 3D printing because it is the most cost-effective process of manufacturing. This is because the traditional prototyping methods like injection molding and CNC machining need several costly machines, and have far higher labor costs as the machines have to be operated by experienced technicians and operators.

When you need small production runs or applications, you can use 3D printing because it is the most cost-effective process of manufacturing. This is because the traditional prototyping methods like injection molding and CNC machining need several costly machines, and have far higher labor costs as the machines have to be operated by experienced technicians and operators.

On the other hand, 3D printing involves fewer machines, about 1 or 2, and a small number of operators to produce a part. Additionally, the method has less waste since making the part is done from the ground up, but it’s not carving from a solid block and doesn’t need extra tooling.

Produces Objects Faster

Among the most significant benefits of 3D printing is rapid prototyping. This is the capacity to design, create, and test a tailored object in the least time possible. Besides, the producers can alter the design without significantly affecting the manufacturing process speed.

Some years ago, before the flourishing of the 3D printing industry, the manufacturers would take weeks to manufacture prototypes. Unfortunately, for any change that they made, they had to add several weeks to the process. As a result, the complete production of a product would take almost a year. However, with 3D, it is possible to design a part, manufacture the item in-house, and do the testing in a few days.

Allows Greater Flexibility

3D printing has another advantage of flexibility in that it is possible for any given printer to make almost anything that suits its build volume. Conversely, with traditional manufacturing, every new part or change in the design of a part needs a new tool, die, mold, or jig to manufacture it to make the new part. Luckily, 3D printing allows flexibility. The producers feed the design into the slicer software, add the needed support, and then print without any change or with little change in the equipment or the physical machinery.…

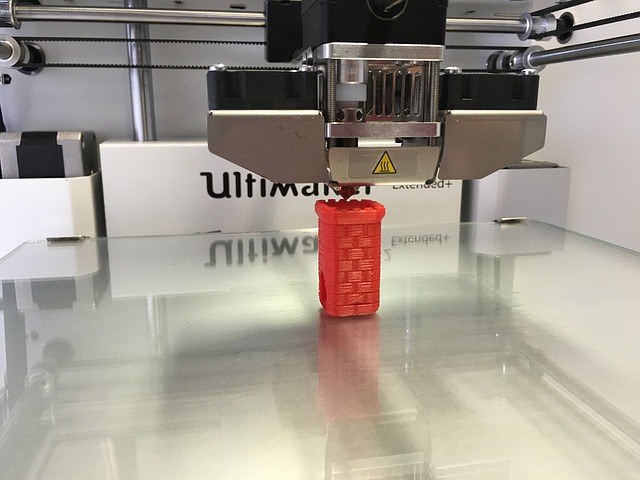

Additive manufacturing can be used in a number of different industries. It is a very useful method of manufacturing that can be very useful to be applied to many various industries. The most common and popular use of additive manufacturing can be found in the aerospace industry. There is aerospace metal 3d printing that can help this industry to manufacture components that they need.

Additive manufacturing can be used in a number of different industries. It is a very useful method of manufacturing that can be very useful to be applied to many various industries. The most common and popular use of additive manufacturing can be found in the aerospace industry. There is aerospace metal 3d printing that can help this industry to manufacture components that they need. Another great thing about additive manufacturing is that you are able to create something that can cater to your needs and customizable to what you want. Plus, you can create something that is complex and historically was too costly or not possible to achieve with conventional engineering. So, you are able to let your imagination run wild and create something that can benefit you.…

Another great thing about additive manufacturing is that you are able to create something that can cater to your needs and customizable to what you want. Plus, you can create something that is complex and historically was too costly or not possible to achieve with conventional engineering. So, you are able to let your imagination run wild and create something that can benefit you.…